FILMJET

DTF ROLL TO ROLL (R2R) PRINTER

Advanced DTF System with Automated Workflow

Designed for high efficiency and high-volume production, Filmjet is a unified, all-in-one DTF system (Printer > Powder Applicator > Oven) that integrates automated processes for continuous operation, consistent quality, and minimal supervision.

who can benefit?

Businesses with high production needs

Ideal for both established businesses and newcomers needing high production capacity.

Designed for DTF printers looking to scale up efficiently.

Recommended minimum output: 2-3 rolls per week (1,500+ transfers at 25×25 cm).

Businesses with demanding requirements

Exceptional color accuracy and reproduction.

Quick support from an EU-based manufacturer.

Industry certifications (GOTS, EcoPassport, CE, etc.).

A healthier working environment with optimized processes.

how Filmjet helps

Cuts DTF-related labor costs by up to 75%.

Increases production capacity and efficiency with automation.

Maximizes uptime for continuous operation.

Delivers stable quality from the first to the last printed meter.

Complies with industry standards and certifications.

high production

FILMJET - TECHNICAL SPECIFICATIONS

| SYSTEM SET-UP | All-in-ONE DTF System (Printer - Powder Applicator - Oven) |

| PRINT HEADS | 4 (2x CMYK + 2x WHITE), Epson i3200 |

| MEDIA WIDTH | 60cm (24 in) Film Rolls |

| INK SUPPLY | Bulk Ink, 4x 1lt CMYK + 2x 2lt WHITE |

| POWER REQUIREMENTS | EU: 3Ph. 380V / 50-60Hz • US: 3Ph. 208V / 50-60Hz |

| OPERATING CONDITIONS | 20-25 °C (68-77 °F), 50-60% RH |

| OPERATING SYSTEM | Windows PC, 12GB RAM, 1TB HD |

| RIP SOFTWARE | User Selection (Additional cost): Cadlink, Ergosoft, Caldera |

| WARRANTY | 1 Year Full Warranty (Print heads included when original supplies are used) |

| DIMENSIONS • WEIGHT | 181(W) x 338(L) x 220(H) cm • 1085 kg |

| CRATE DIMENSIONS • WEIGHT | 205(W) x 325(L) x 155(H) cm • 1500 kg |

features

Smart System Control

The system continuously monitors media position, executing system processes only when necessary for optimal efficiency.

Manage all functions from a single 10-inch touch screen. Modern and easy to use UI. Real-time notifications. Film length tracking. Winding direction selection. Ink level monitoring. Precise powder control. Curing profiles.

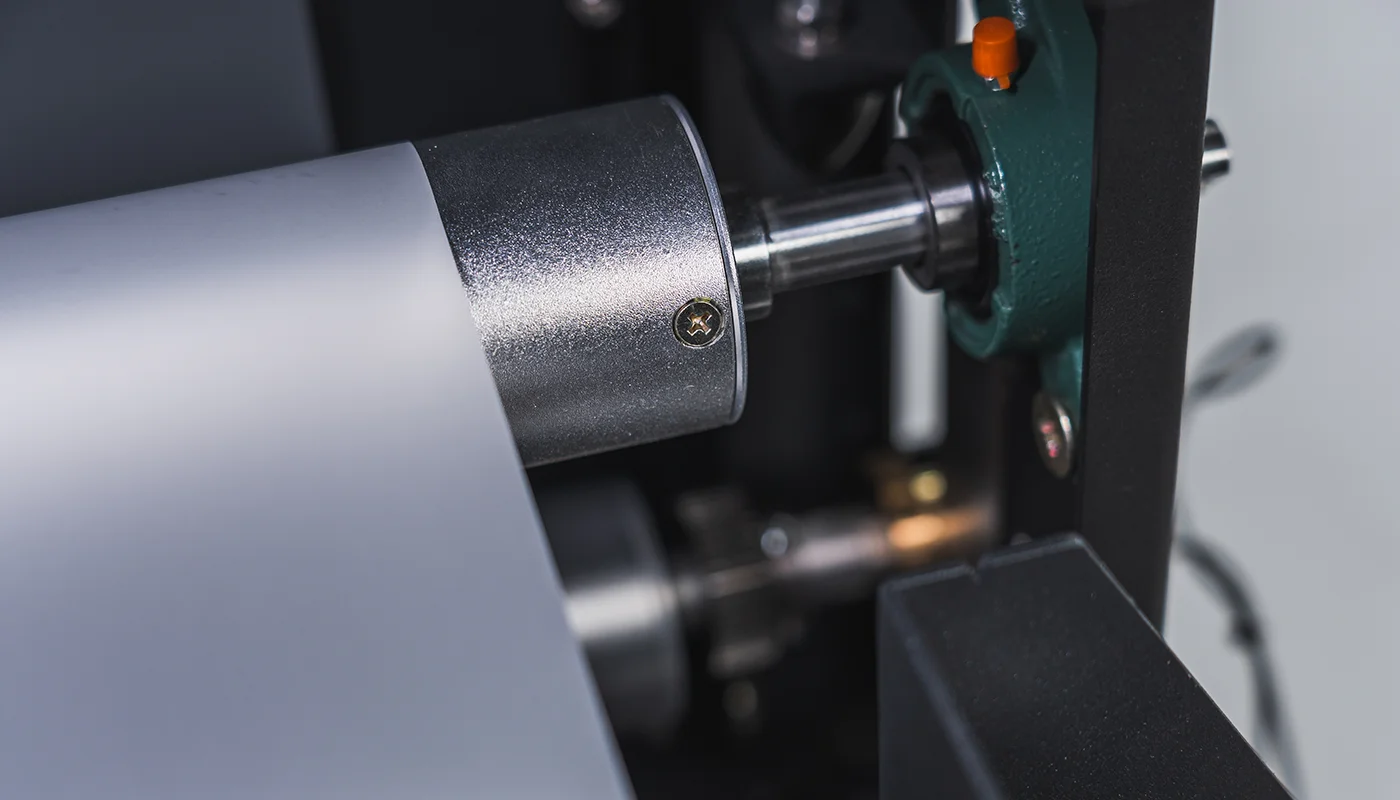

Constant Film Tension

A unique feature that offers significant benefits compared to common “film-shaking” DTF technology, ensuring:

Straight and stable film movement without sideways shifting. No risk of film crushing on printheads. Reliable long-run printing. Precise and uniform film winding. Automatic excess powder removal via air/vacuum technology.

Reliable Curing

The oven is equipped with four adjustable heating zones, each with two fast-response lamps, and bottom reflective curing to ensure optimal results.

Curing profile presets. Oven-cooling on top and bottom to keep temperature stable. Protects film from overheating when printing stops.

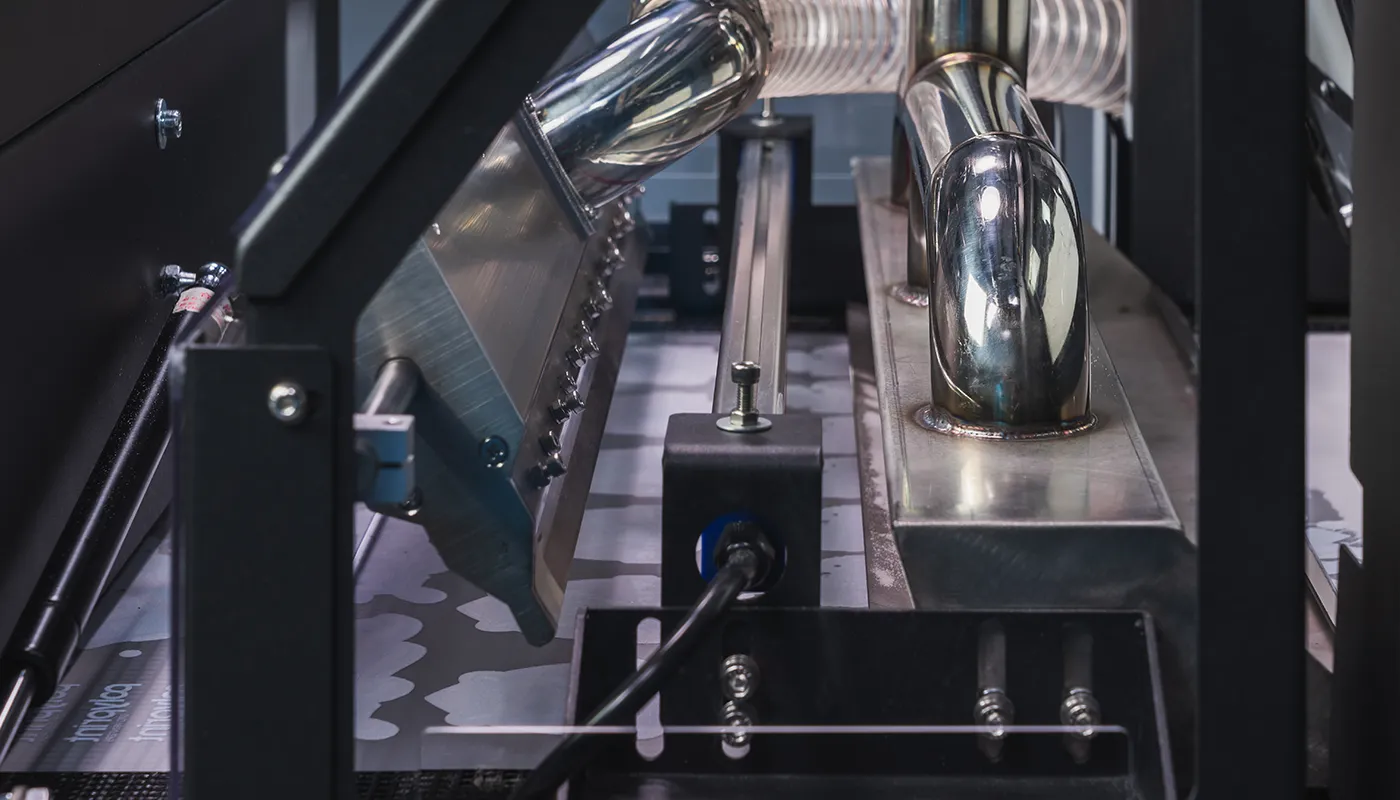

Auto Powder Application

A fully automatic mechanism precisely applies regulated powder amount, ensuring uniform diffusion. Excess powder is recycled via an automatic system, transferring it to separate containers atop the central tank for reuse.

Auto Powder Removal

An adjustable air vacuum, coupled with an “air knife,” efficiently removes excess powder by redirecting it back into the suction area. Additionally, an antistatic bar neutralizes static electricity onto the film to prevent powder adherence and maintain cleanliness.

Excellent Ink Performance

Controlled ink pressure provides superior printing results and stability surpassing basic gravity-fed ink systems.

Controlled Ink Pressure. Ink Circulation (WHITE). Ink Agitation (CMYKW). Wet Wiper.

4x i3200 Printheads

Optimal spacing between printheads ensures CMYK drying before White ink application, maintaining quality even in fast print modes through printhead overlap.

Send us a message

Interested in the Filmjet DTF system? Contact us today for more details on features, availability, and pricing!

consumables

Filmjet Inks

Developed for reliability and consistency, Filmjet Inks Series delivers vibrant colors, deep blacks, and superior white opacity with less ink. Featuring a wide color gamut, it is non-hazardous under GHS standards, Ethylene Glycol-free, and HAPS-free.

Filmjet Films

Filmjet Films deliver reliable, high-quality transfers for any DTF application. Under heat, they remain dimensionally stable, anti-static, and scratch resistant, ensuring clean, precise image transfers with a matte finish.

Filmjet Powder

Filmjet hot melt adhesive powder ensures a soft, flexible finish with superior adhesion to synthetic and natural fabrics, including polyester, nylon, rayon, blends, and cotton.